The DarkRoom is multi-layered rapid prototyping and production program that involves a multi-faceted approach to research & development. The principle of the DarkRoom program is to develop, hone and refine our products at a much quicker pace allowing BOTE to remain at the forefront of innovation in the SUP industry. The DarkRoom provides our engineers and product developers with a playground for experimenting with advanced materials and production techniques in a controlled environment.

Physically, the DarkRoom occupies close to 15,000sqft of space in our Ft. Walton Beach corporate campus. Spread throughout the space are some of the latest and greatest computer controlled machinery, highlighted by a 18’ 4-axis CNC mill and 3-D Plastic Printers.

The DarkRoom isn’t just a space; its a project with a purpose.

DESIGN

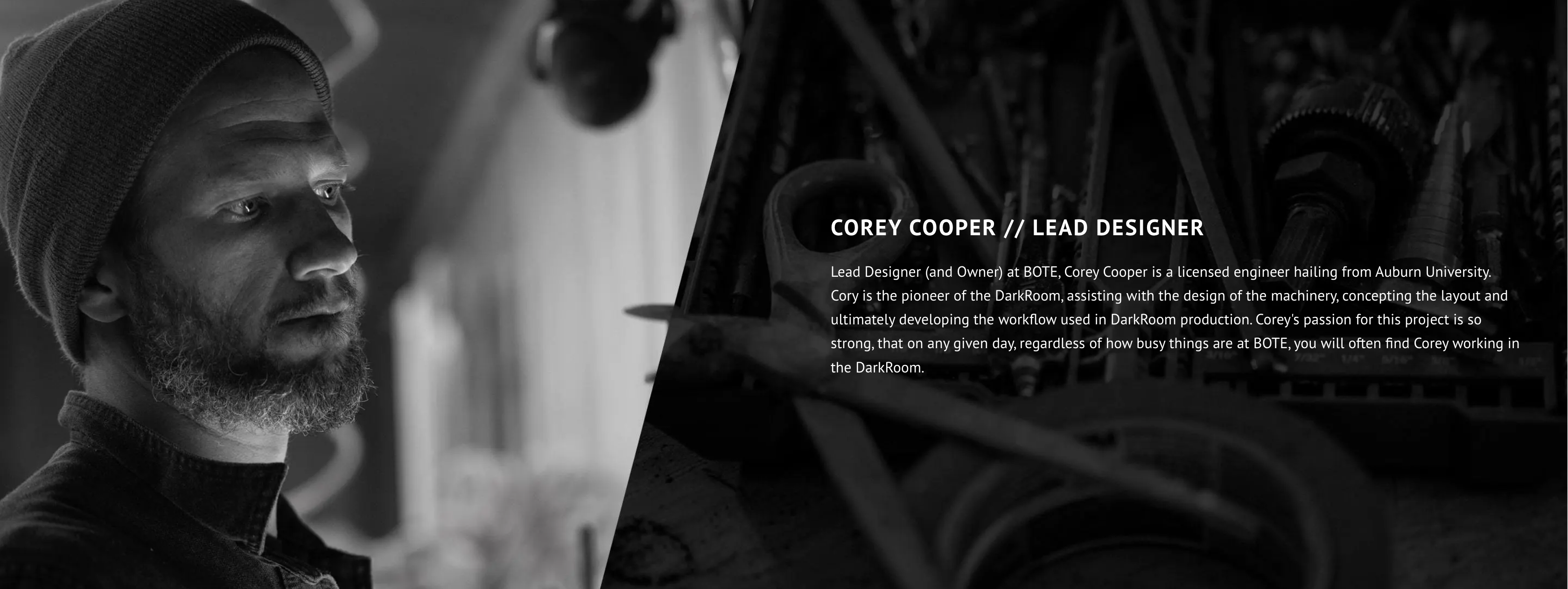

Each new board design that works it's way through the Darkroom, begins with an idea born from a combination of necessity, curiosity and customer feedback. Using the latest CAD based software allows our lead designer, Corey Cooper, to rapidly explore and manipulate board shapes with extreme precision.

MATERIALS

In the darkroom we are constantly experimenting with custom materials to produce our boards. Always looking for lighter, stronger and more environmentally sustainable materials to improve product performance. We work closely with materials manufacturers to explore the various strengths and weakness of a variety of materials compositions and weaves.

TECHNOLOGY

The star of the DarkRoom is undoubtedly the shaping machine. The machine is a 4-Axis CNC Mill with a 17' capacity. Built in collaboration with Mike Ewaliko from Precision Shapers, the custom machine is equipped to handle all of our radical deck cutouts, nose shapes, and bottom contours. With an accuracy of 1mm, there are really no limits to the complexity of our designs.

RAPID PROTOTYPING

CONCEPT

Each new board design that works it's way through the Darkroom begins with an idea that is born from a combination of necessity, curiosity and customer feedback.

CAD DESIGN

Advanced CAD based software allows our lead designer, Corey Cooper, precise control over the board design.

CARVE

4-Axis CNC Mill with a 17' capacity and an accuracy of 1mm has virtually limitless capabilities to carve rough shapes from foam blanks.

SHAPE

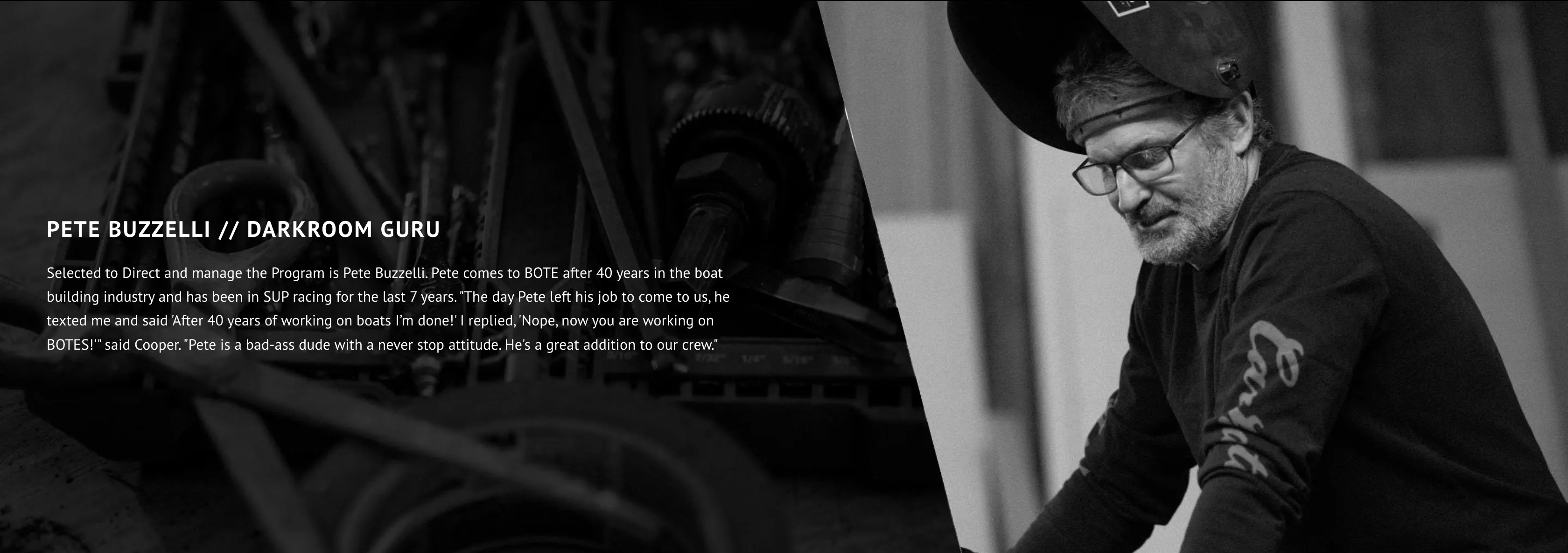

Each rough shape is hand hewn to perfection by our Darkroom Gurus.

LAMINATION

Foam blanks are laminated using the latest advanced and highest quality materials available.

FINISHING

Each board coming out of the DarkRoom is polished to perfection and then undergoes a rigorous quality assurance examination.